|

|

|

|

Our Thermoform Plastic Sheets are perfect for inventors, small businesses, and DIY hobbyists who want to make custom vacuum formed plastic parts. Use these plastic sheets along with with our Hobby Vacuum Formers and a kitchen oven to thermoform homemade plastic parts with results that rival expensive commercial machines. Make your own plastic prototypes, clamshell and blister packaging, custom molds, scale model parts, and movie props.

Due to its low cost and superior physical properties, ABS (Acrylonitrile-Butadine-Styrene) is one of the most popular thermoform plastics used for vacuum forming. ABS produces detailed parts that are tougher and more rigid than other plastics. It is manufactured in both black and white with a “haircell” texture on one side that helps resist and hide scratches, making ABS a popular choice for parts that need to stand up to heavy use. See our Common Thermoform Plastic Questions & Answers Section below for more details.

-

Recommended Uses for ABS Thermoform Plastic Sheets:

-

Prototypes and Production Parts, Plaster and Concrete Molds, Theater Props

|

Technical Specs for 3/32" BLACK ABS Plastic Sheets

|

|---|

-

Thickness:

- 3/32" thick (See All Thicknesses)

- Color:

- Opaque Black (See All Colors)

- Texture:

- Haircell texture on one side, smooth on the other

- FDA Food Safe:

- No

- Strength:

- High rigidity, Good impact strength

Excellent scratch/abrasion resistance

- Forming Temp:

- 325 - 350 degrees F

- Machining:

- Cut, drill, and sand with woodworking tools

- Decoration:

- Painting not recommended

- Common Example:

- Retail displays, Interior walls/seat backs of commercial aircraft

|

|

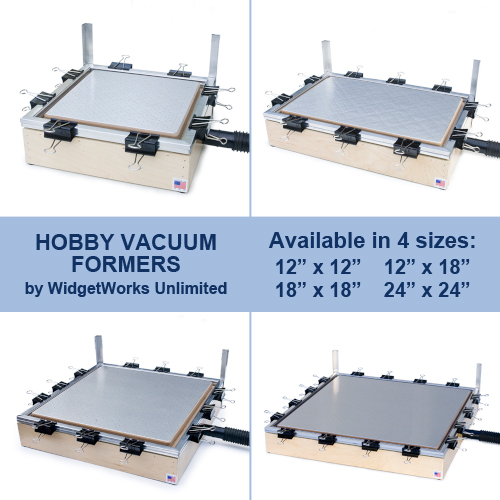

Make Magazine's Holiday Gift Guide featured the WidgetWorks Unlimited

12x12 Hobby Vacuum Former in their Top 10 Gifts to Give an Inventor/Hacker.

|

|

How To Vacuum Form Plastic At Home in 3 Easy Steps

|

|---|

- STEP 1: Secure your thermoform plastic between the Hobby Vacuum Former's metal clamping frames with the provided spring clips. Attach your Shop-Vac (not included) to the vacuum former. Place your model on top of the vacuum formers perforated aluminum platen.

- STEP 2: Place the thermoform plastic in your kitchen oven and watch as it begins to sag. When the plastic becomes soft, remove it from the oven. Align the metal clamping frames with the Hobby Vacuum Former's guides and lower the plastic over your model.

- STEP 3: The hot thermoform plastic forms an air tight seal around the edges of the aluminum vacuum platen. Vacuum pressure pulls the hot plastic down around the model. After cooling for a few seconds the thermoform plastic part hardens and is ready to be removed.

|

|

Common Thermoform Plastic Questions & Answers

|

|---|

-

What Kinds of Plastic Can You Vacuum Form?

- Our Hobby Vacuum Formers are compatible with all thermoform plastics, including: ABS, Acrylic (also known as Plexiglas), Butyrate, PET-G, Polycarbonate (also known as Lexan), Polyethylene, PVC, Styrene, and Vinyl.

- Checkout our Vacuum Forming section for thermoform plastic in a variety of colors and thicknesses. We recommend that customers who are new to vacuum forming start by molding a few practice pieces in Styrene. This type of thermoform plastic is "extra stretchy" when hot, which makes it easier to form around tight corners and into small details. It also has a large forming temperature window, giving beginners a little more time to handle it and form it before it cools and becomes hard again.

-

What Else Do You Need To Get Started Vacuum Forming?

- Hobby Vacuum Former made by WidgetWorks Unlimited LLC.

- Kitchen oven

- Shop-Vac style vacuum cleaner with 1 1/4" hose (or larger vacuum with 1 1/4" adapter)

- Leather gloves to protect your hands while holding the hot plastic / metal clamping frames

- Model or mold to form the hot plastic around

-

Will Your Kitchen Oven Work With Our Thermoform Plastic Sheets?

-

Thermoform plastics become soft and formable when heated to 250-350º F. Most kitchen ovens are perfectly suited for the job. Both electric and gas ovens can be used with good results. If you have an "efficiency" kitchen or live outside the USA, we recommend that you measure the inside of your oven to verify that the plastic sheets can fit inside.

-

Will Your Shop-Vac Vacuum Work With Our Thermoform Plastic Sheets?

-

Most vacuum cleaner motors produce 4 to 5 in Hg (inches of Mercury) vacuum pressure, which means that most vacuums are equally suited for vacuum forming, regardless of their size. Larger vacuums with higher horse power will remove air from the former a fraction of a second faster than small vacuums, but their forming pressure (the force that pulls the plastic tight against the mold) will basically be the same.

-

What Materials Can You Use to Make Vacuum Forming Molds / Models?

-

Molds can be made out of any material that will not deform under vacuum pressure: wood, metal, plastic, plaster, and clay are all good choices. Choose a material that is easy to work with using the tools at your disposal.

|

|

|

|

|

|

|

|